Hog Hammers

Johnson Hog Hammers

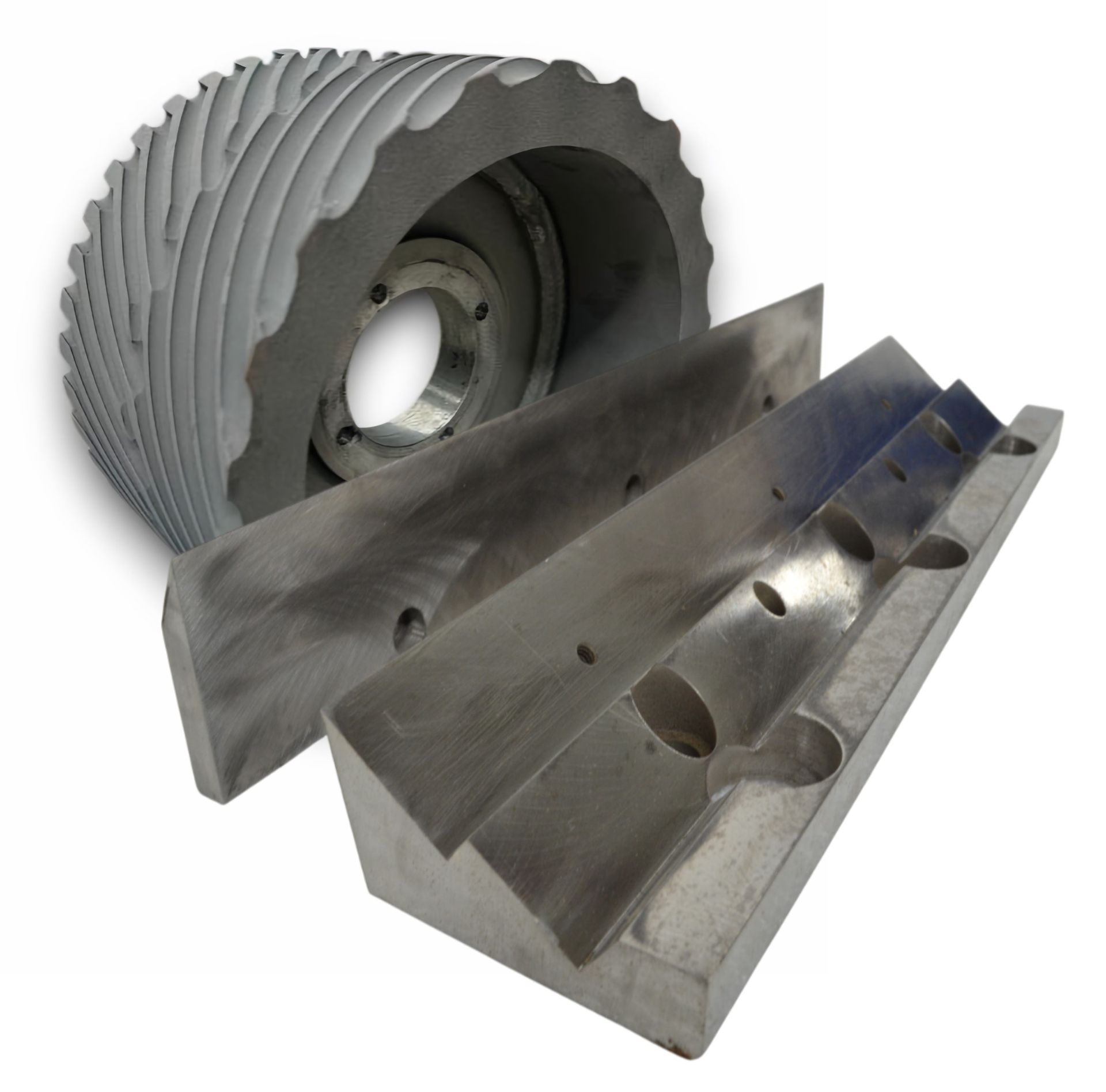

Hog hammers are a critical component of a hog mill or grinder, a machine used in the wood processing industry to reduce wood waste into smaller pieces or particles. The hog hammers are typically mounted on a rotating shaft and impact and shred the wood material as it passes through the machine.

Johnson Enterprises manufacture high-quality hog hammers designed to withstand hog mill operations’ high impact and abrasion. We fabricate our hog hammers from high-grade steel alloys with a specialized tungsten carbide coating.

Johnson Enterprises offer a variety of hog hammer configurations to suit different applications and wood types. We design our hammers to be easily replaceable, which helps minimize downtime and maintenance costs.

Johnson's Various Types of Hog Hammmers

Johnson manufactures and refurbishes various types and styles of hog hammers by applying our extreme carbide process. It drastically improves their performance and endurance. Customers can rely on Johnson Enterprises for quality hog hammers that will help optimize their hog mill’s performance and ensure efficient and effective wood waste reduction.

Hog Hammer Screen

Hog hammer screens are the main factor in determining the consistency of the finished particle size. The screen is positioned over the discharge opening, ensuring no material evacuates the grinding chamber until it meets the target finished particle size.

Johnson can refurbish or manufacture a hog hammer screen with a special wear plate to enhance the duration and life span.

Our Other Products

Debarker Arm

Debarker tips

Feed Rolls

Chipper & Planer Parts

Debarker Parts

Learn moreHardware & Items

Learn moreLet’s build something powerful together.

Call Us

Email Us

Opening Hour

Mon - Thu : 7 am – 4 pm

Fri : 7 am – 12:45 pm

Sat - Sun : Closed

Address

69 Chem. Lac des Lys, Val-d’Amour, NB

Contact us

Contact Us

We will get back to you as soon as possible.

Please try again later.