Hydro Sector

Powering Clean Energy Infrastructure

Hydropower is one of the most sustainable and scalable energy sources in the world. But behind every turbine rotation and megawatt delivered is a set of precisely engineered components that make it all possible. At Johnson Enterprises, we support the hydroelectric industry by manufacturing and refurbishing the critical mechanical parts required for new installations, retrofits, and long-term maintenance.

With over 40 years of manufacturing experience and ISO 9001:2015 compliance, we understand the technical challenges of hydroelectric operations. From dam gates and penstocks to turbine shafts and generator housing, our machining and fabrication services deliver performance, safety, and long-term durability for every component we touch.

Process

Our Role in the Hydroelectric Process

Machined and fabricated parts play a role at nearly every phase of hydroelectric power generation. During the construction of hydroelectric plants, we supply custom-fitted components that are integrated into turbine systems, intake structures, and structural frameworks. These parts must meet extremely tight tolerances to ensure system efficiency and to prevent costly misalignments or failure.

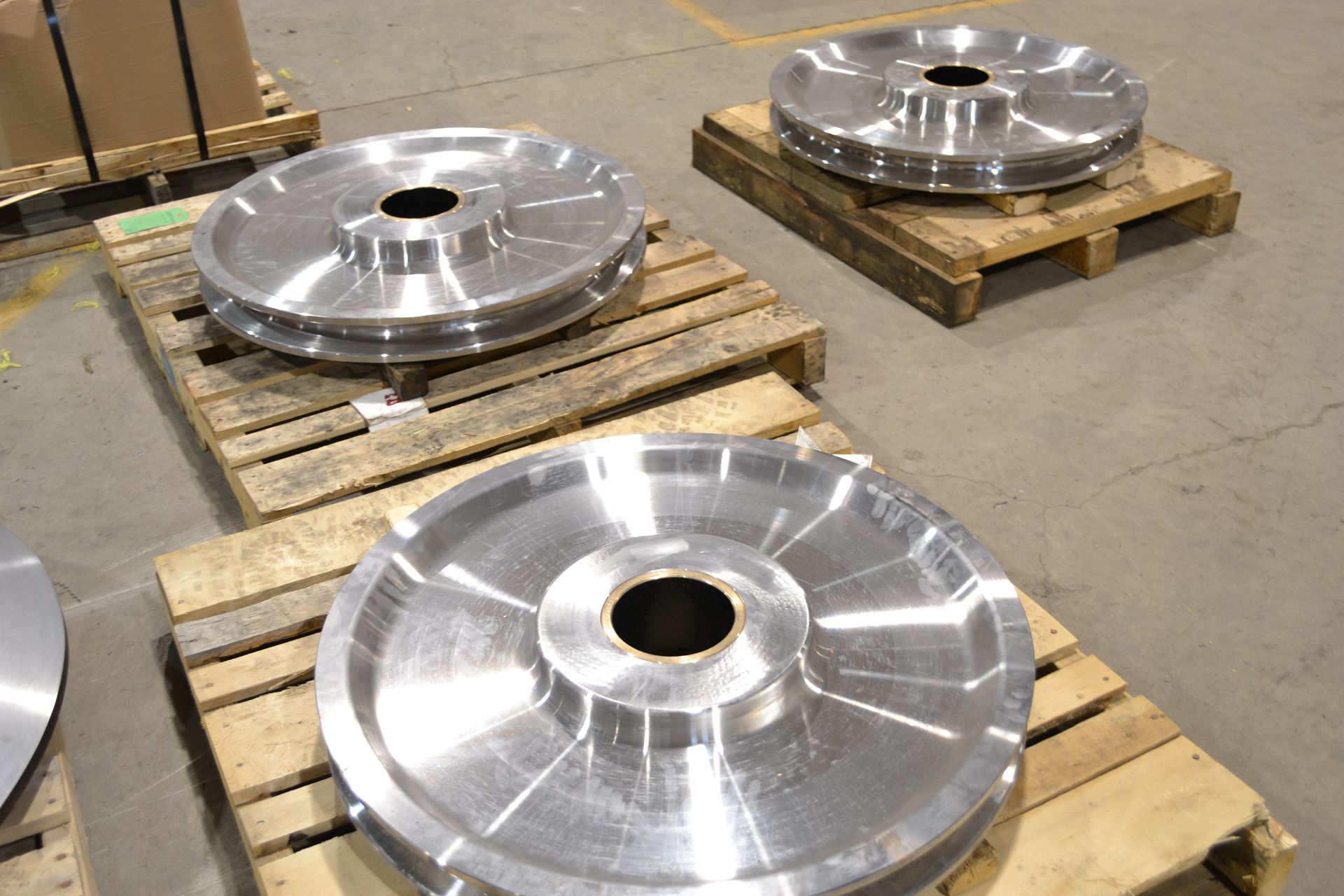

Once the plant is operational, we provide repair and refurbishment services for turbine runners, generator shafts, casings, and wear components that degrade over time due to water erosion, vibration, and fluctuating loads. Our machining team is trained to replicate OEM dimensions, and our fabrication shop can reconstruct large assemblies with full material traceability and QA documentation. For power utilities seeking reliable lifecycle management, Johnson Enterprises is a trusted Canadian supplier.

Typical Components We Manufacture and Refurbish

Our team has extensive experience producing custom hydro components such as turbine blades, wicket gates, runner hubs, guide vanes, and rotor shafts. We also fabricate and machine structural elements such as base plates, bearing housings, and stator frames.

All components are built using high-grade steel, stainless alloys, and coatings selected for hydraulic resistance and fatigue tolerance. In refurbishment scenarios, we perform reverse engineering, surface reconditioning, and rebalancing to OEM or upgraded specifications. Every component is inspected, measured, and delivered with accompanying MTRs, dimensional reports, and heat treatment certifications.

Regional Presence, National Impact

From the rolling rivers of New Brunswick to the massive hydro installations of Quebec and Ontario, Johnson Enterprises has built strong partnerships with public utilities, private energy providers, and infrastructure contractors. Our location in Val-d’Amour places us at the heart of Eastern Canada’s hydro grid, giving us the flexibility to respond quickly to urgent demands while supporting long-term projects.

We take pride in being a Canadian-owned and operated company with the technical expertise and responsiveness of a dedicated local partner.

Precision Services for Critical Hydropower Assets

At Johnson Enterprises, precision is more than a word—it’s a discipline. In the hydro sector, the consequences of vibration, imbalance, or dimensional error can lead to mechanical inefficiencies, costly downtime, and even safety risks. That’s why our machining department operates under a strict quality system and is equipped with high-speed CNC mills and lathes, as well as advanced measuring equipment including CMM (Coordinate Measuring Machines).

From new fabrication projects to emergency part replacement or long-term preventative maintenance contracts, our team collaborates with utilities, turbine manufacturers, and EPC contractors across Eastern Canada to keep hydro assets running at peak performance.

Let’s build something powerful together.

Call Us

Email Us

Opening Hour

Mon - Thu : 7 am – 4 pm

Fri : 7 am – 12:45 pm

Sat - Sun : Closed

Address

69 Chem. Lac des Lys, Val-d’Amour, NB

Contact us

Contact Us

We will get back to you as soon as possible.

Please try again later.